It was with great pride that we celebrated the official inauguration of our anaphoresis line in Dugny yesterday, in the presence of Quentin Gesell, Mayor of Dugny and Metropolitan Councillor of Greater Paris, and Bruno Coiffier, General Manager of Purchasing at Dassault Aviation, as well as our customers and partners, in particular PPG. 👏 ✈

This anaphoresis facility enables Satys to offer an innovative, REACH-compliant anti-corrosion protection technology for aeronautical parts, significantly reducing the environmental footprint and production cycles.

We sincerely thank the Dassault teams for their renewed confidence and support.

And a big thank you to all our customers, including Airbus Helicopters, but also all our partners and institutional players who have renewed their trust in us for over 30 years.

#pride #supplychain #filièreaéro #traitementsurface #aeronautique #success #airbus #aero #reach

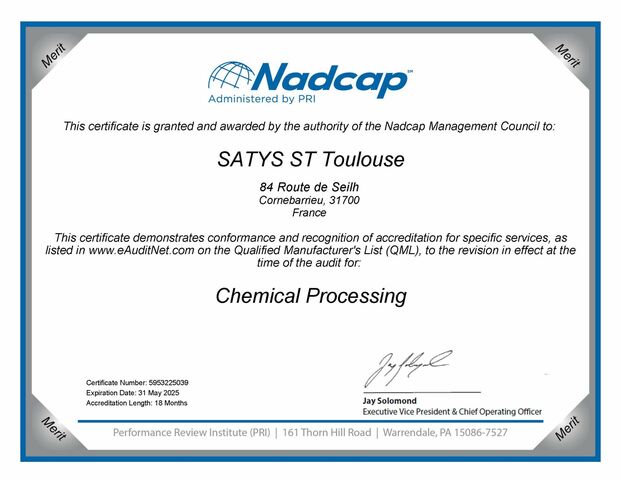

Satys Surface Treatment Toulouse has renewed its NADCAP "Chemical Processing" certification.

Once again, our teams have been awarded the MERIT PROGRAM, proof of their commitment and a just reward for their efforts.

#NADCAP #traitementsurface #aero #chemicalprocessing

SATYS Surface Treatment Toulouse joins Satys Sealing & Painting France, Satys Surface Treatment Marseille, Satys Surface Treatment Nord and Satys Sealing & Painting Maroc already associate members of SPACE Aero 🚀.

The SPACE Aero association offers its member companies a range of services designed to improve industrial performance and competitiveness within the supply chain of the civil aeronautics and space industries.

#Collaboration #IndustrialExcellence #aero #surfacetreatment

Dr Erno Gorgenyi (Mayor of Gyula), Kristof Szalay-Bobrovniczky (Hungarian Defence Minister), Christophe Cador (CEO of Satys) and Laszlo Palkovics (N7 CEO)

Opening of our new Surface Treatment Plant in Hungary.

We were happy to celebrate Thursday, Frebruary 16th 2023 the opening of our new Surface Treatment JV in Gyula, Hungary, with our parner N7 with Kristof Szalay-Bobrovniczky (Hungarian Defence Minister), Laszlo Palkovics (N7 CEO), Dr Erno Gorgenyi (Mayor of Gyula). 👏

This aeronautical parts surface treatment plant in Gyula is mainly dedicated to our customer Airbus Helicopter Hungary (AHH) .🚁

Christophe Cador CEO of Satys and László Jakab COO of N7

Partnership in Hungary for surface treament.

As part of Satys Aerospace's development in surface treatment, a partnership was signed with the Hungarian company N7, for the building of an aeronautical parts surface treatment plant in Gyula, Hungary, with Airbus Helicopter Hungary (AHH) as its main customer..

For Satys Surface Treatment Toulouse's 30th anniversary, we had the pleasure to welcome our most valued customers and partners who visited our facilities and had the chance to appreciate the changes carried out during the summer.

We would like to thank our customers for their trust and our partners for their contribution over the last 30 years.

This was the opportunity to thank all our employees with a friendly event too!🥳

SATYS Surface Treatment Team is pleased to announce the qualification of SAO NG( Sulphuric Anodic Oxidation New Generation) for SAFRAN VENTILATION SYSTEMS.

This qualification adds to the qualifications already acquired for SAFRAN VENTILATION SYSTEMS on Penetrant Testing / Classic OAS / Alodine 1200 /Passivation / Painting treatments.

Within the framework of a project called “Easynov” financed by the Occitanie Region and Europe via an ERDF fund, the Rutile project, named for titanium ore, is the Satys Surface Treatment project to regenerate titanium chemical milling baths for the industry and environment through partnerships with INSA, LMDC (educational partner) and LR Vision.

How the project started?

Satys Surface Treatment ( ex PRODEM) has been using chemical milling for almost 30 years to decontaminate, strip and lighten titanium aeronautic parts. This process produces huge quantities of final waste which is called “spent baths”. This waste is not recycled and has a significant impact on the factory’s operating costs.

The Satys R&D team has been looking for the last several years for a way to regenerate “spent baths” in order to reduce costs and help the environment.

Three years ago a process was invented based on a physico-chemical method used to precipitate the titanium.

A patent has been pending for this process since 2017 and an international patent was filed in 2018.

Following this finding, a project was put together with educational partners both private and from the Occitanie region in order to further develop this process on an industrial scale.

Satys Surface Treatment will present the project at the 46th A3TS congress in Lille on July 3 and 4, 2019.