Activities

Aerospace

AIRCRAFT SEALING & PAINTING

AIRCRAFT SEALING & PAINTING

World leader in new aircraft painting.

Repainting of commercial aircraft for companies, leasers but also business jets.PARTS & SUB-ASSEMBLY PROTECTION

PARTS & SUB-ASSEMBLY PROTECTION

French leader of composite treatment..

SURFACE TREATMENT

SURFACE TREATMENT

Cutting-edge services in surface treatment

Interiors

RAILWAY

INTERIORS

A recognized know-how in aircraft interior design.

Who are we ?

Satys, a key player in the booming transport industry

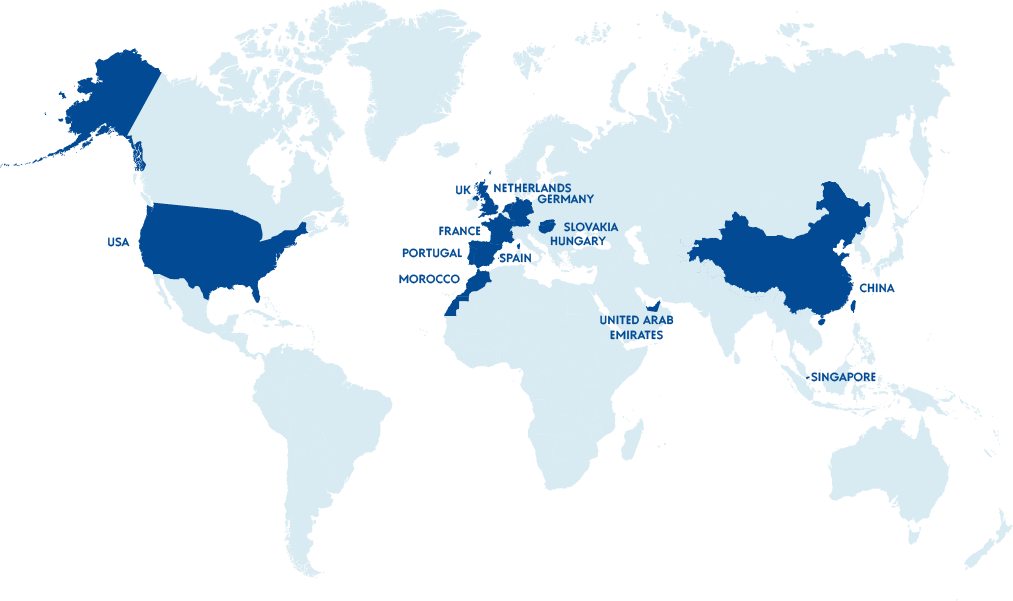

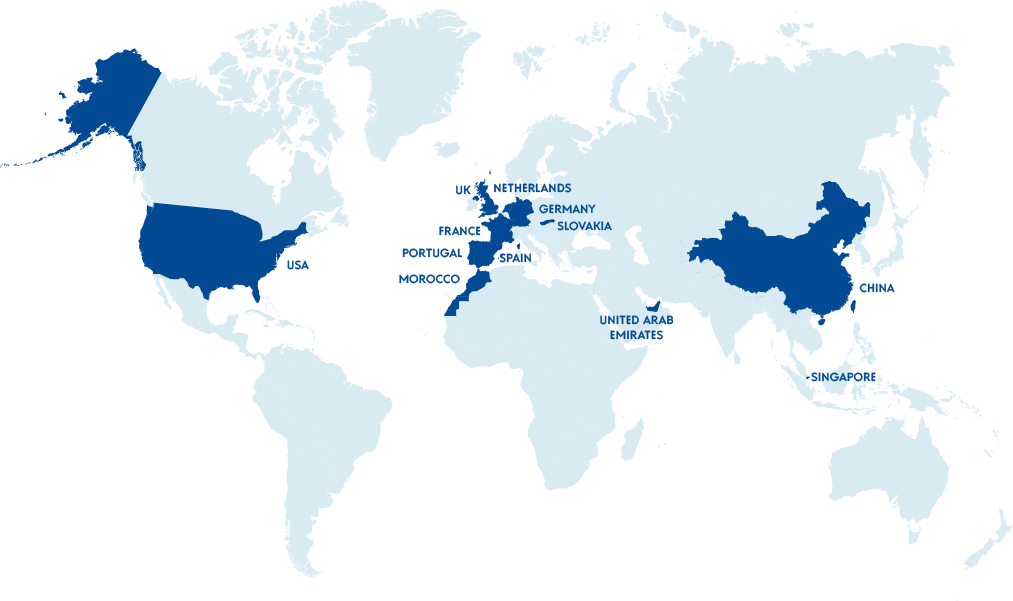

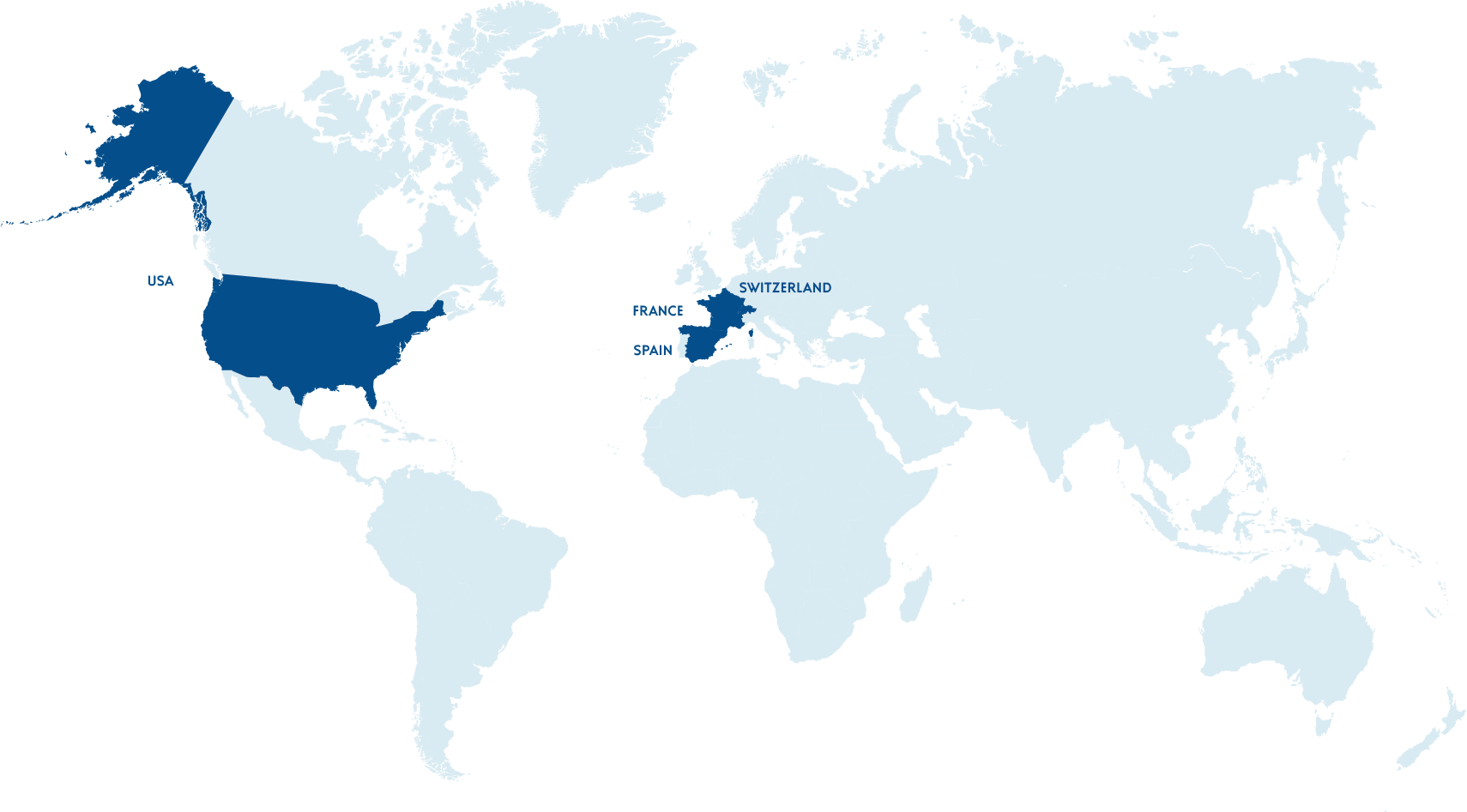

Satys is a French industrial and international group, present in 13 countries with 52 sites in Europe, North America, the Middle East, Asia and Africa. Its headquarters have been in Blagnac (Occitanie, France) since the foundation in 1986 under the name STTS.

Satys is active in aircraft painting,sealing and manufacturing interiors for aerospace and rail sectors.

The group employs 2 600 people worldwide and has numerous certifications . The group also has a surface treatment activity as well as a research & development division in its subsidiary Expiris.

Christophe Cador's interview

Partner with large companies, Satys aims to deliver on time

Christophe Cador, CEO of Satys since 1999, traces the history of the company, its values and development projects.

What was your vision of the aeronautics market when you took over STTS in 1999?

It wasn’t a sector that I knew very well, but I had in mind that the aeronautic industry was growing, due to Airbus’ remarkable products. I had also understood that Airbus didn’t want to do everything itself on its aircraft.

The company was looking for reliable partners, for example in painting, who would be able to invest and support its development. This was also the case for our other customers such as Air France. That’s how we were able to build, finance and operate our first paint hanger in Blagnac in 1999. Following in Airbus’s and Air France’s footsteps was in the beginning the motor of our development.

Christophe Cador, CEO of Satys since 1999, traces the history of the company, its values and development projects.

What was your ision of the aeronautics markets whan you took over STTS in 1999 ?

It wasn’t a sector that I knew very well, but I had in mind that the aeronautic industry was growing, due to Airbus’ remarkable products. I had also understood that Airbus didn’t want to do everything itself on its aircraft.

The company was looking for reliable partners, for example in painting, who would be able to invest and support its development. This was also the case for our other customers such as Air France. That’s how we were able to build, finance and operate our first paint hanger in Blagnac in 1999. Following in Airbus’s and Air France’s footsteps was in the beginning the motor of our development.

But is wasn't the only vision ?

No, because we decided to add an international dimension to the company while still supporting Airbus and our other customers. We first opened a paint hangar in Seville, then in England, in the Netherlands… As a result, it has never stopped.

We are now present in 14 countries including China, where we started our business in 2009. Satys is a French company with its headquarters in Blagnac, and will remain there as we are firmly attached to this location. However, more than half of our activity is done abroad. And without this development we wouldn’t have become what we are today.

Diversification has always been a driving force in your development strategy...

Indeed. I am very attached to the painting activity which was our first market, but I was able to identify early on the need to diversify in order to strengthen the company’s position. For example, the rail industry is a sector where we have become a major player concerning amenities. And we have clear ambitions in this area . In total, the Interiors divisiont accounts for 35% of our annual turnover. And this part linked to production will continue to progress because growth is a driving force for the future of our company. I would like to add that all activities are important for Satys because the customers have placed their trust in us.

Christophe Cador : « Our success is primarily that of the French aeronautic industry. Without Airbus' tremendous success, we wouldn't be here. »

How do you see the future of Satys ?

First of all, we have to do our job right which means delivering aircraft on time in order to earn our customers’ trust. Then, both divisions Satys Aerospace and Satys Interiors each have ambitious roadmaps for the years to come.

We plan to invest 350 million euros until 2025 to create new paint hangars or surface treatment plants as well as improving those already in existence. We also intend on making new acquisitions, to achieve 500 million euros in annual turnover in 2025, even if an increase in activity isn’t an objective in itself.

So what is the most important for you ?

I like to keep in mind that we must first safeguard our markets to better develop. Satys is an industrial player in the transport industry with the intention of becoming one of the leaders in each of its sectors. But I cannot forget that to remain a preferred partner of the big companies we have to deliver on time.

What is the secret to you success over the last twenty years ?

Our succes is first that of Airbus’ success which tripled the number of aircraft delivered in 20 years. Without Airbus’ tremendous success, we wouldn’t be here. But the key to the success of Satys is our team of more than 3 000 employees in France and abroad because nothing happens alone.

Our strength also comes from constantly completing and complementing our team from new recruits and talents already present in the companies we have acquired. Our employees are loyal: those who were there in the beginning are still here except for any who retired along the way. Next, each new contract won, each activity created was a key moment in our development. And these markets were won with audacity, creativity and long-term investment.

To sustain this internal dynamic, we have to constantly give meaning to our strategy and explain our projects. I am a leader who works closely with my colleagues in the workshop, the design office and cross-functional departments. I strongly believe that this closeness is the secret to the company’s success. We have also put together a new organization. I have complete trust in Fabien Roualdes and his teams to contribute to the company’s success.